Robotics

Applied operational robotics

Make your operations future-proof , give direction to your operational strategy for optimal automation outcomes!

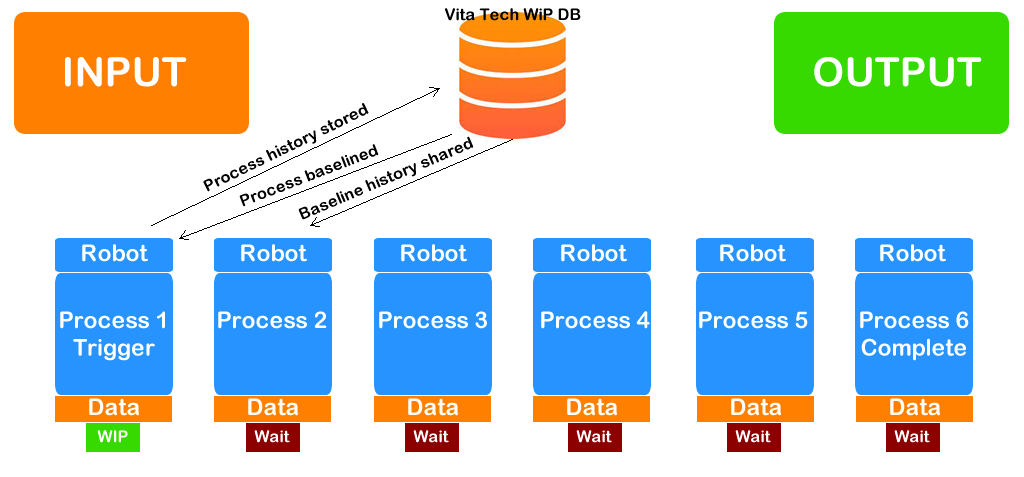

Work-in-Process Automation

Work processes can be arduous and repetitive, consisting of labour-oriented workflows across different activity streams. Specific processes can be targeted with contemporary robotics for efficient output to a particular segment of the overall workflow. With network technologies, highly integrated partial work-in-process segments can be automated with targeted efficiency gains. These tasks can be compartmentalized for general orientation of processes. These processes need not be heavy manufacturing based, but for true Work-in-Process Automation, tangible processes are necessary.

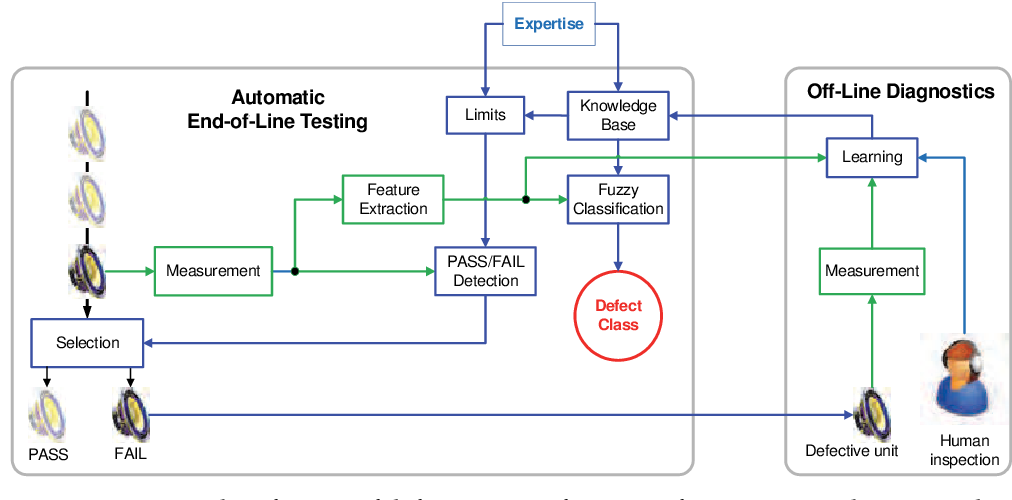

End-of-Line Handling

Conventional understanding affirms that packaging plays a critical role in sales transactions and consumer satisfaction. Factors such as aesthetics, ergonomics and consistency of packaging enhance appeal for repeat sales cycles, leading to possibly extended revenues. With End-of-Line Handling, packaging is automated, which provides the needed consistency for product/process visual and safety orientation .

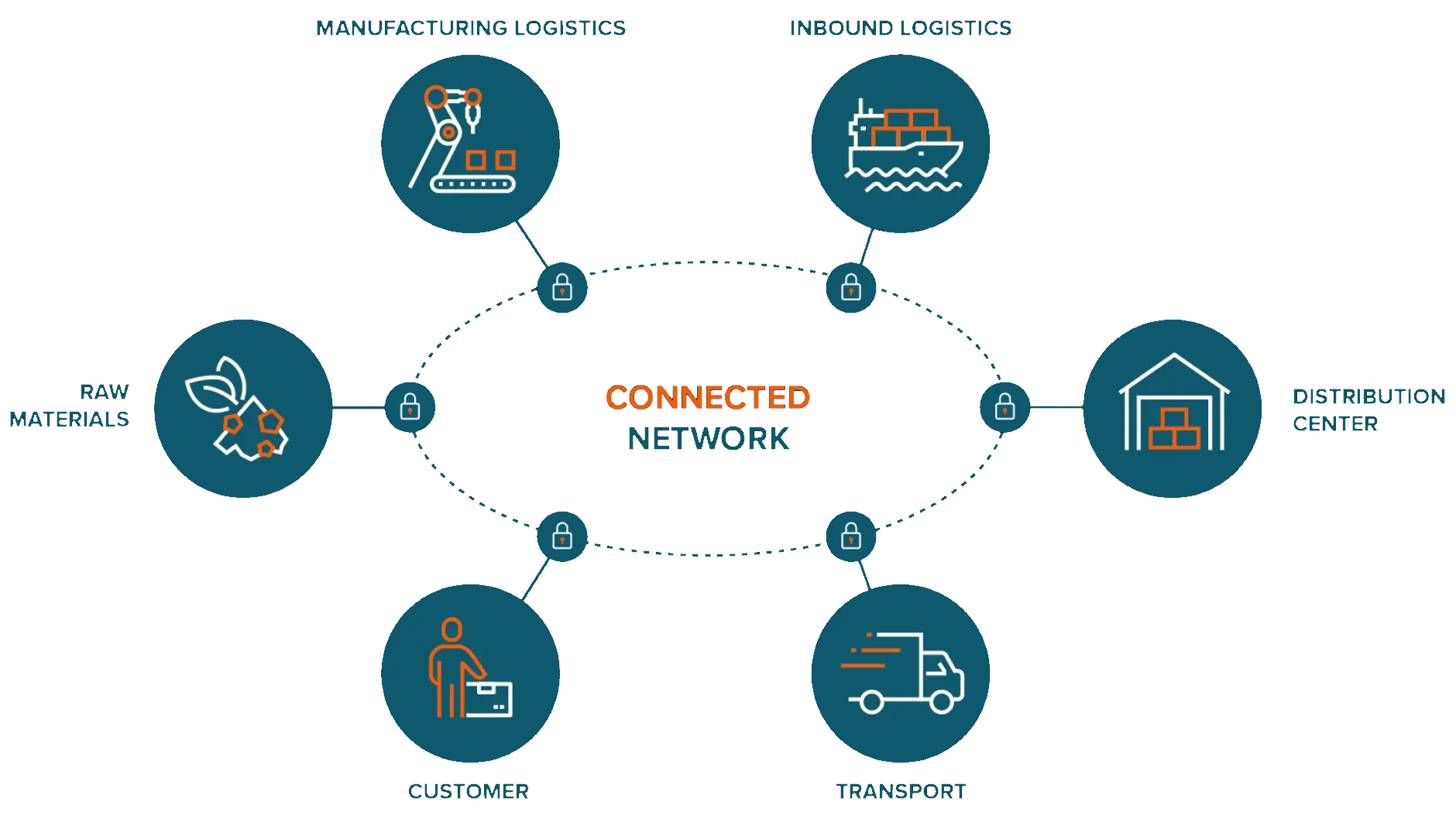

Materials Transport Workflows

Once products are packaged, there is a transitional process between packaging and distribution, by ensuring earliest deliveries, particularly for perishable goods, product lifecycle can be improved which enhances customer satisfaction. Materials Transport Workflows can also be utilized in the actual manufacturing process, making input materials to key production transformational processes more seamless eventually reducing manufacturing timelines. .

Inventory Management Solutions

Storage of key produce is an important component in distribution and effective tracking. While every manufactured item is tracked and labeled for value creation, effective management allows for seamless distribution and effective closure to transactions. Studies have confirmed how organized storage and warehousing enables efficient distribution. Solutions need to be tailored to important organizational workflows and manufacturing orientations and with alignment, business processes can be automated for mechanistic and predictable outcomes.